Mother Nature provides all living creatures with the energy they need. Sustainable civilization can be achieved by mimicking natural mechanisms with innovative processes. Innovation itself is hidden in nature. Chitin is the main ingredient in the exoskeletons of arthropods and crustaceans and is also in the cell walls of fungi. Among many other creatures, beetles, lobsters, crabs and shrimp have chitin in their protective armors.

Chitlig scientist developed a revolutionary method that is promising to obtain biodegradable polymer from endless (partly renewable) non-animal sources such as Sahara dust, shale and shale like material which was formed by organic materials over geologic time. The patent-pending invention will enable us to produce industrial scale input material with low environmental impact and at low cost given the abundance of the source material. Chitlig scientists promise that the new biopolymer resulting from their process will be naturally allergen free, and biodegradable.

Possible Use of “The new biopolymer”

-

Biomedical

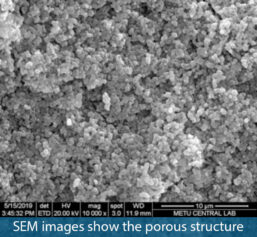

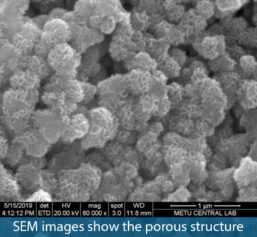

Chitin-based biopolymer promises to be the basis of biomedical applications because of its high porosity, biodegradability, non-toxic and high biocompatibility. These properties of newly invented biopolymer will lead to significant research studies in biomedical and pharmacology applications such as drug delivery, tissue engineering, wound-healing, and 3D organ printing. Due to its immediate blood stopping ability and antimicrobial properties, similar biopolymer-based wound healing products are currently used by the militaries of the U.S.

-

Agriculture

Chitin derived biopolymer can be used in various areas of agriculture such as fertilizers, pesticides and anti-fungal protection. As a pesticide, biopolymer would help the plant to defend itself naturally against various pests, such as fungi, bacteria, and insects. The new biopolymer can be of great use in the food industry, for example in production of edible films to control the moisture and fungi transfer from the environment into the food. Hence, biopolymer can increase the shelf life of packaged agricultural products for up to 2 weeks.

-

Bioplastics

Chitlig scientists were able to produce bio-based plastics using The new biopolymer in a laboratory. The final plastic products from The new biopolymer are biocompatible, biodegradable, and can be easily molded into complex shapes. It is thus a potential replacement for conventional petroleum-based plastics in applications ranging from consumer products to medical uses. The innovative biomaterial will play a key role in the transition to a circular economy, where fossil raw materials are substituted by sustainable resources.